3 Ways To Rock QuickBooks Inventory

Are you always running out of product and scrambling to reorder?

Are you always running out of product and scrambling to reorder?

Or maybe you’re trying to find space to cram just a couple more product boxes into your storage area?

You’re probably forgetting about inventory counts, tracking, and inventory review.

These will help you keep products on hand to sell and manage storage space.

Let's walk through how to manage and absolutely rock QuickBooks inventory.

Inventory Counts

I cannot stress this enough: inventory counts are crucial. Initially, it feels comparable to cleaning out the fridge.

It really needs to be done, but does it have to be done right now? It can be put off until next month, right?

Without inventory counts, you don't know what is in your inventory. Those numbers don’t appear magically out of the air.

The good news is they don't have to be painful. Just three simple steps.

- Schedule a time to get it done.

Scheduling an inventory count on a regular basis can also help to make it seem less painful. It can be monthly, quarterly, or biannual as long as it is on a regular schedule. - Make a plan.

If you know what items (don't worry about quantity yet) should be in your inventory, make a list. - Get people to help you!

The best inventory counts happen with everybody working together. Grab the volunteers and unpaid interns, too.

Keep your list for future counts; then, you can easily reuse it and update it with any new product.

And make it fun, order pizza. The team that suffers together and eats pizza together stays together!

Track Your Inventory

Record Sales

After you’ve counted your inventory, you need a way to record what should be going out so you can compare quantities the next inventory count.

Inventory Management Software like Fish Bowl or point-of-sale (POS) software makes this very easy.

Enter each item into the software so that it is recorded every time it sells, then import a daily sales summary with item details or invoices into your QuickBooks file.

Need help deciding on a particular brand of software? Contact us for help with your Point of Sales software and integration into QuickBooks.

Record Purchases

Record incoming items by inputting purchases from vendors, and then using item details on purchase orders (and on the bills) in QuickBooks when items are received.

Review to Increase Efficiency - AKA Profits

If you've made it this far in the blog, we're going to throw some equations at you now.

After you have a grip on what is in your inventory, you can ask questions to help you make your inventory work better for you. This is where QuickBooks can become truly remarkable.

Once you have the information input into your POS, the books start to take shape. You'll be able to use the numbers produced to increase the efficiency of your inventory and collect profit.

Reducing waste alone is a great help to increasing the bottom line.

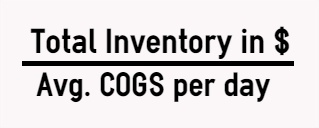

How many days' sales of inventory?

To calculate the day's sales of inventory, ask yourself: If you stopped purchasing any new items, how long would it take you to sell out of everything?

To acquire this number, divide your inventory amount by the cost of goods sold (COGS) in a day.

In order to change the day's sales in inventory, you need to think about two things:

How long does it take to resupply?

You know it'll take about 7 days to go through 7 apples (or oranges if that's what you're selling) but the vendor takes 3 days to deliver to you! You can't wait until the last day to order.

Take an average of how many of each item sells every day, multiply that by how many days delivery takes, and that is your very last day for when you have to order.

In this example, the daily average is 3, so I would place an order for 9 apples when my quantity falls to 4 apples.

What is the lifespan of the product?

If an item becomes obsolete or expires in a month, I don’t want my days of sales in inventory to be more than a month. Otherwise, I’ll be losing product and potential sales due to spoilage.

Use the lifespan against the day's inventory sales to determine the maximum amount of product that can be kept on hand.

For example, I know the apples can last two weeks. If I move the equation a bit:

-

Day's sales in inventory = Total inventory/COGS in one day.

-

Day's sales in inventory X COGS in one day = Total inventory.

The equation will give us the dollar amount for our total inventory.

However, we want to find the maximum quantity we can have in inventory to avoid spoilage loss.

So, finding the best amount of inventory to have on hand can be found in a few different ways:

-

Divide COGS in one day by avg. product cost; Substitute in for COGS in one day

-

Check reports at the POS

-

Inventoried items in QuickBooks

To make sense of this, I know I sell an average of one apple a day. I know that an apple will keep for two weeks. This means that I can keep 14 apples in my storage at a time, which is the maximum number of apples that I want at a time.

In the end, I want between 3 and 14 apples at any given time in my inventory.

What is the profitability of each product?

If you are recognizing the costs of each product when you sell it, you can quickly and directly see how much profit you are making.

Sure, apples are selling, and I'm making a 25 cent profit on each one, but those oranges are selling for a lot more. It might be time to downsize those apples and order more oranges.

Comments